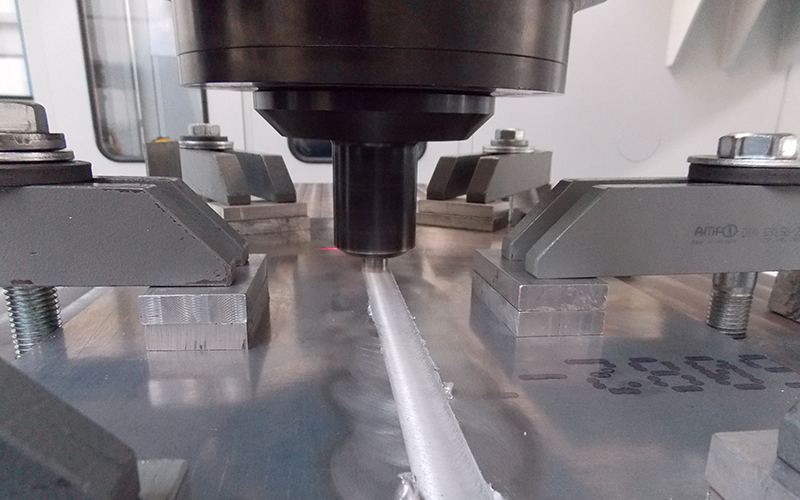

AMM Manufacturing operates in the field of rail industry and specialises in the production of aluminium and steel parts for trains, subways and trams. Putting the quality of its products above all, AMM Manufacturing has over time found partners and become a renowned supplier to the world’s largest manufacturers in the rail industry such as: Alstom, Siemens, Hitachi, Stadler, Skoda, CAF. AMM exports directly throughout Europe and to the Russian Federation, and indirectly to other parts of the world. AMM is set apart from the competitors by its product quality, its ceaseless striving to upgrade knowledge and skills, and by introducing new technologies. AMM introduced friction welding in its curriculum last year. It is considered to be the ‘greenest’ welding technology owned by only a few companies in Europe.

The success we are proud of rests upon continuity of partnership with large customers and product quality in a demanding industry such as rail.

Year of establishment:

2017

Location:

Kragujevac

Founder and owner:

Bratislav Milanovic

Business information

| 2021 | 2015 | 2010 | 2005 | |

|---|---|---|---|---|

| Full-time employees | 530 | / | / | / |

| Turnover (EUR) | 20.7 m | / | / | / |

| Export (EUR) | 13.3 m | / | / | / |

PRODUCTS/SERVICES

COMPANY DEVELOPMENT AND ENTREPRENEURIAL STORY.

The founder of AMM Manufacturing, Mr. Bratislav Milanovic, founded his first company in Germany in 1990. After a decade of successful business, he decided to start a business in Serbia, and in 2000 he established “Milanovic Engineering”. Originally a small engineering bureau, it grew into a large manufacturing company engaged in the production of components for rail vehicles, metal machining and water purification plants. Years of successful business and proven product quality have led Siemens Mobility, then the largest customer, to take over “Milanovic Engineering.” At that time an idea was born to continue already established cooperation with large buyers. AMM Manufacturing was established and took over cooperation with Alstom, Bombardier and Hitachi Rail, while expanding to new collaborations such as Skoda Transportation, ABB and Deutchebahn. The turning point in AMM Manufacturing ‘s business was the decision to set quality as the highest priority and to organise the company in a way that guaranties all the necessary certificates needed in the rail industry. Thus we ensure long-term cooperation on some of our biggest projects.

CONTRIBUTION TO SUSTAINABLE DEVELOPMENT GOALS

AMM invests resources in staff training and is involved in projects aimed at raising the employability of young people, people with disabilities and other hard-to-employ categories. By introducing friction welding (a green technology implemented by a handful of companies in Europe) we are reducing waste in the production process at AMM Manufacturing and upgrading: resource utilisation energy efficiency and environmental protection.

AMM Manufacturing’s staff have the opportunity to undergo the youth training programme in addition to continuous soft and hard skills training within the company. Dual education is focused on the profiles of locksmith-welder, industrial mechanic, electrician, operator.

Dozens of high school students undergo training for machining and computer control technicians. AMM is part of the “dual education in higher education” programme. At AMM Manufacturing the students are trained in the field of economic engineering – mechanical engineering. In addition, we are involved in providing professional internships to students of mechanical engineering, but also economics and management.

We actively cooperate with student organisations, but also we organise independently a number of competitions, seminars and workshops for young people. Our aim is to train the staff for the future and to encourage other companies in the area to join the projects we are already part of.